Categories

PRODUCT

Product Lists (1)

::SCIENTIFIC::

Autoclaves (2)

Bag Mixers (4)

Circulator Baths-> (2)

Dehumidifiers (1)

Furnaces-> (8)

Giant Hotplates (1)

Homogenizers / Disperser (2)

Incubators (2)

Ovens (2)

Overhead Stirrers (2)

Shakers (1)

Shaking Incubators (2)

Ultrasonic Cleaners (1)

Weighing Scales / Balances (5)

::PCB PROTOTYPING::

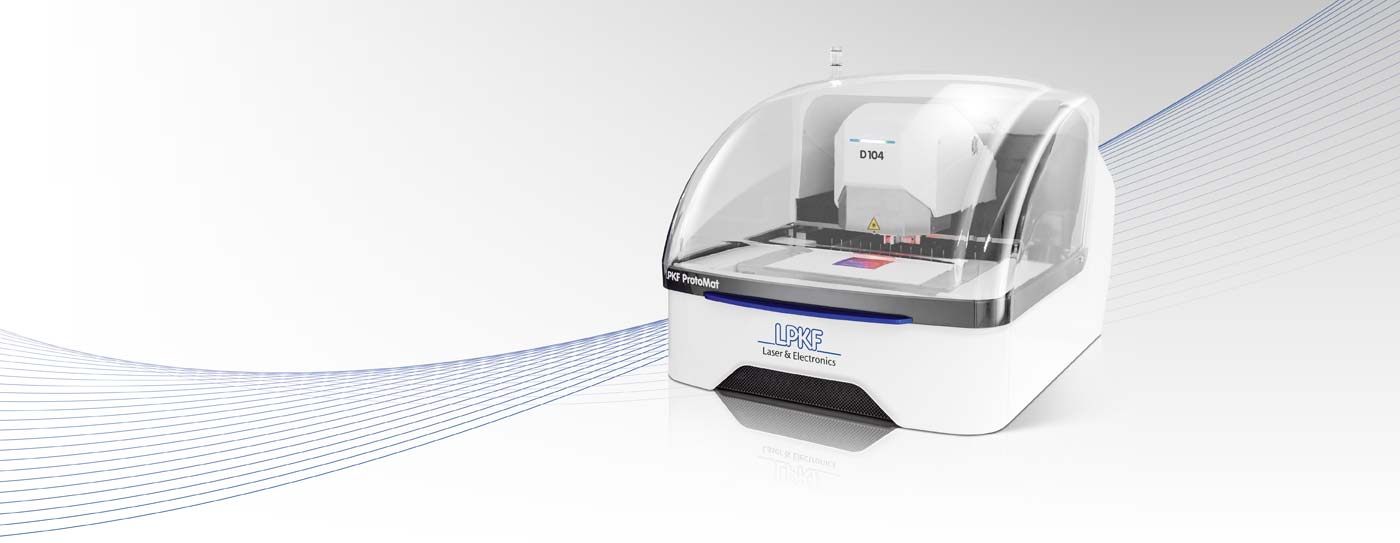

PCB Plotters (4)

Laser Circuit Structuring (2)

Through-Hole Plating (3)

MultiLayer (1)

Solder-Resist Masks (1)

SMT Assembly-> (4)

Tools (1)

Consumables (3)

::LDS TECHNOLOGY::

LDS Equipment (2)

Product Lists (1)

::SCIENTIFIC::

Autoclaves (2)

Bag Mixers (4)

Circulator Baths-> (2)

Dehumidifiers (1)

Furnaces-> (8)

Giant Hotplates (1)

Homogenizers / Disperser (2)

Incubators (2)

Ovens (2)

Overhead Stirrers (2)

Shakers (1)

Shaking Incubators (2)

Ultrasonic Cleaners (1)

Weighing Scales / Balances (5)

::PCB PROTOTYPING::

PCB Plotters (4)

Laser Circuit Structuring (2)

Through-Hole Plating (3)

MultiLayer (1)

Solder-Resist Masks (1)

SMT Assembly-> (4)

Tools (1)

Consumables (3)

::LDS TECHNOLOGY::

LDS Equipment (2)

Information

| Thursday 31 October, 2024 | 6272186 requests since Tuesday 04 October, 2011 |

Copyright © 2024 Angle Technology

Powered by Angle Technology Co., Ltd.

32/213-214 Moo 6 Bang khan-Nong Sua Rd., Khlong Sam, Khlong Luang, Pathum Thani 12120 Thailand

Tel: (662) 901-1723-4

Fax: (662) 901-1722

Email: [email protected]